In-house mould-construction

Continuously Schonlau engineers construct new cast iron slats, in order to fulfil increasing requirements of modern animal husbandry.

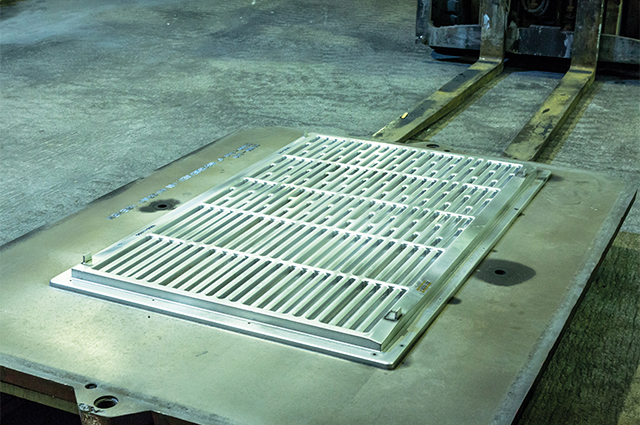

Casting track | sand mould

The “open mould process” needs just one bottom mould. This sand frame is being used just once. After the casting process this special sand is going to be prepared for repeated use.

Casting process

Each cast iron slat is manufactured individually under visual control. By the use of FERROCAST® cast iron slats achieve the well-known outstanding quality.

Only the „open mould process“ avoids any flashes or fins between cast iron bars due to the absence of a top mould frame.

Cooling track

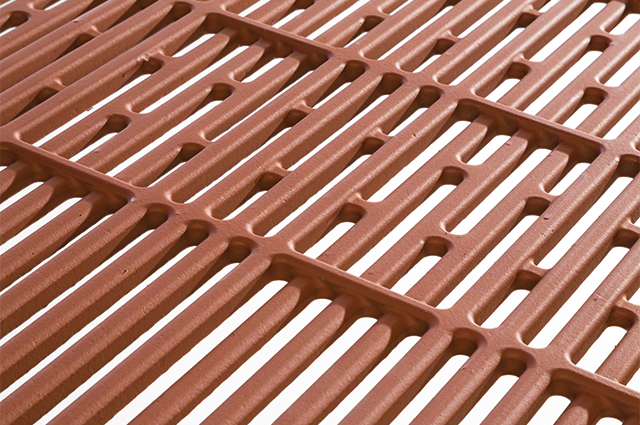

FERROCAST® cast iron slats cool down until they reach room temperature. Finally slats are taken out of the mould frame and then they are sandblasted. Grinding of flashes, fins or any further sharp edges is not necessary. The natural roundly shaped bars assure outstanding foothold and avoid injuries.

Finishing

For the last “finish” the slats passes a coating layer. The dipping colour provides excellent protection against corrosion.

Strict examination

FERROCAST® cast iron slats are manufactured acc. ISO 9001, and are being examined acc. DIN 11848 up to a load of 1100kg (100 x 100 mm). Regularly representative random sample tests out of the running production guarantee a worldwide unique animal friendly flooring.

Ferrocast®

FERROCAST® show an exceptional elasticity on mechanical pressure – but only a FERROCAST® slat immediately regain its previous even shape – in opposite to a ductile (nodular) cast iron slat.

Pickup / delivery

We are happy to deliver the goods inexpensively through our forwarder.